|

Blacksmithing, an ancient craft that dates back thousands of years, is experiencing a renaissance in the modern world. Traditional blacksmithing techniques are being combined with cutting-edge technologies, leading to exciting innovations in the field. From artistic creations to practical applications, modern blacksmiths are Forging the future with their skill, creativity, and embrace of new tools and techniques.

One of the most significant innovations in modern blacksmithing is the use of advanced materials. While iron and steel remain fundamental to the craft, blacksmiths are now experimenting with exotic alloys, composite materials, and even unconventional mediums like glass and ceramics. These new materials offer enhanced strength, durability, and aesthetic possibilities, allowing blacksmiths to push the boundaries of their artistry. In addition to digital design, automation has found its place in modern blacksmithing. Robotics and CNC (Computer Numerical Control) machines are being used to perform repetitive tasks with speed and accuracy. This automation frees up blacksmiths to focus on the creative aspects of their work, enabling them to produce more intricate and unique pieces. However, it's important to note that hand Forging skills and the human touch still play a crucial role in maintaining the authenticity and soul of the craft. The integration of technology has also revolutionized blacksmithing. Computer-aided design (CAD) software and 3D printing have opened up new avenues for designing intricate and complex metalwork. Blacksmiths can now create detailed digital models and transform them into physical objects with precision and efficiency. This fusion of digital and physical craftsmanship has empowered blacksmiths to bring their wildest visions to life. Furthermore, modern blacksmiths are embracing the concept of sustainability and environmentally friendly practices. Traditional blacksmithing relied heavily on coal and other fossil fuels, contributing to air pollution. However, innovative approaches like electric forges and clean energy sources are being adopted, reducing the carbon footprint associated with the craft. Blacksmiths are also recycling scrap metal and repurposing materials, turning waste into valuable resources. By prioritizing sustainability, modern blacksmiths are Forging a greener future for their craft. Blacksmithing is not limited to traditional tools and weapons anymore. The field has expanded to encompass a wide range of applications. Modern blacksmiths are creating stunning sculptures, intricate jewelry, architectural features, and even functional everyday objects. Their work can be found in galleries, public spaces, and private collections around the world. The versatility of the craft allows blacksmiths to express their creativity across various disciplines, blurring the lines between art, design, and practicality. Moreover, the resurgence of interest in blacksmithing has led to the establishment of educational programs and workshops. Aspiring blacksmiths can now learn the craft from experienced professionals, either through apprenticeships or formal training. This transfer of knowledge ensures the preservation of traditional techniques while also fostering innovation and experimentation. The community of modern blacksmiths is vibrant and collaborative, with enthusiasts sharing ideas, techniques, and inspiration through online forums and in-person gatherings. Modern blacksmithing is a dynamic and evolving craft that combines ancient traditions with innovative practices. The integration of advanced materials, digital design, automation, and sustainable approaches has propelled blacksmithing into the future. Blacksmiths today are pushing the boundaries of their art, creating awe-inspiring works that blend craftsmanship, technology, and creativity. As this ancient craft continues to Forging ahead, it inspires a new generation of artists and inventors, ensuring that the legacy of blacksmithing remains strong for years to come.

0 Comments

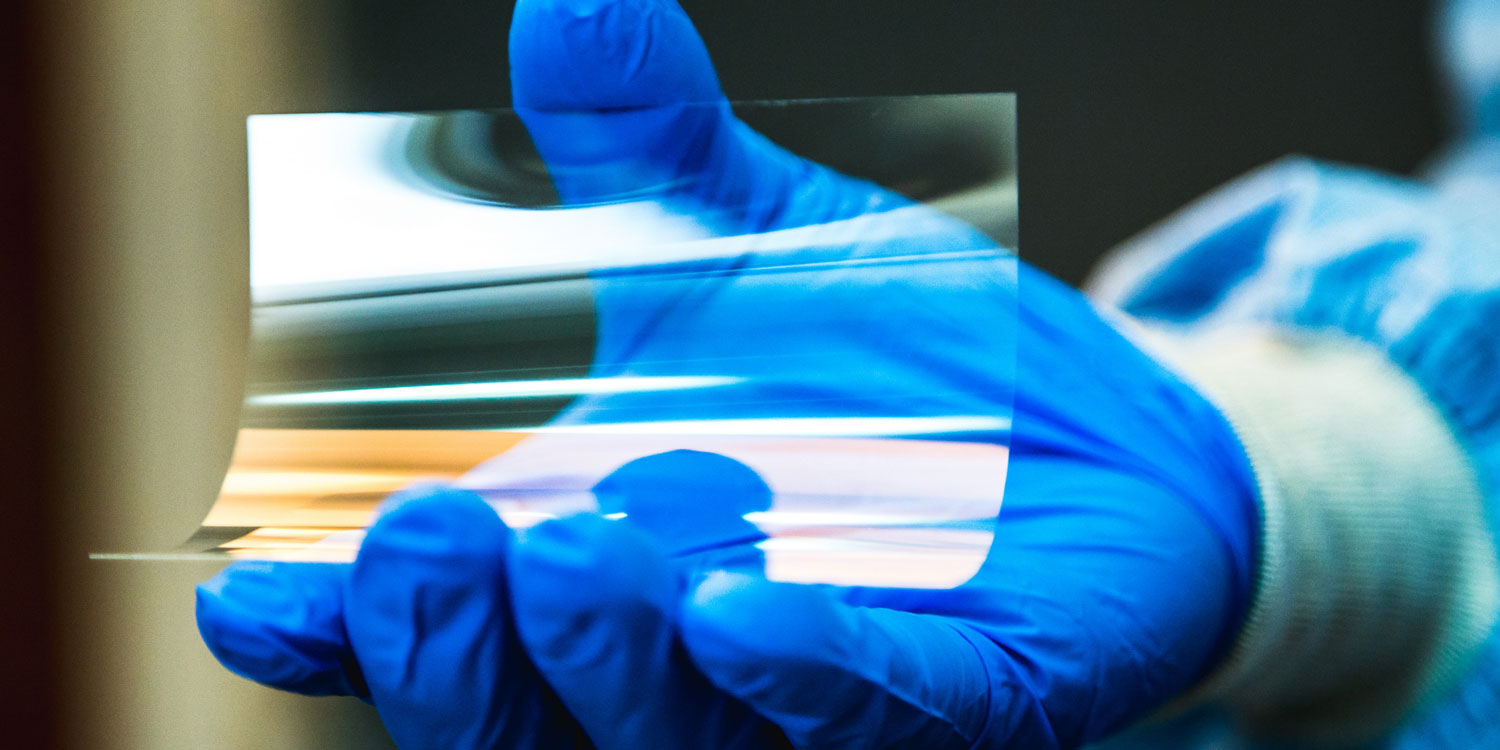

In recent years, wearable technology has become increasingly prevalent, integrating seamlessly into our everyday lives. From smartwatches and fitness trackers to augmented reality glasses, these devices have revolutionized how we interact with technology. One crucial component that has played a pivotal role in enhancing the functionality and aesthetics of wearable devices is Ultra-Thin Glass. With its exceptional properties and versatility, ultra- fine glass is reshaping the world of wearable technology.

Ultra-fine glass, as the name suggests, refers to a type of glass that is incredibly thin, measuring only a few micrometers in thickness. Despite its thin profile, it boasts remarkable strength, durability, and transparency, making it a perfect material for wearable devices. This specialized glass is often made using advanced manufacturing techniques, such as float glass or chemical vapor deposition, which ensure its uniform thickness and consistent quality. One of the significant advantages of Ultra-Thin Glass in wearables is its exceptional flexibility. Wearable devices are designed to conform to the contours of the human body, and the flexibility of ultra-fine glass allows for a more comfortable and ergonomic fit. This flexibility enables wearables to be seamlessly integrated into various forms, such as curved displays or wraparound screens, providing a superior user experience. Additionally, the flexibility of ultra-fine glass reduces the risk of cracking or shattering, ensuring the longevity of wearable devices. Another key benefit of Ultra-Thin Glass is its outstanding optical properties. The glass is remarkably transparent, allowing for vibrant and high-resolution displays in wearable devices. This transparency enhances the visual experience and enables wearers to view content with exceptional clarity. Whether it's checking notifications on a smartwatch or immersing oneself in augmented reality through smart glasses, the optical properties of ultra-fine glass bring visuals to life like never before. Furthermore, ultra-fine glass offers excellent scratch resistance, protecting wearable devices from everyday wear and tear. The glass is often coated with specialized materials, such as diamond-like carbon or oleophobic coatings, which enhance its scratch resistance and repel fingerprints. This ensures that wearable devices retain their pristine appearance even with continuous use, adding to their longevity and overall value. The lightweight nature of Ultra-Thin Glass is also a significant advantage for wearable technology. Wearable devices are meant to be worn comfortably for extended periods, and the reduced weight of ultra-fine glass contributes to a more enjoyable user experience. This lightweight characteristic is especially crucial for applications like smart eyewear, where the comfort of the user's face is a primary concern. The combination of flexibility and low weight makes ultra-fine glass an ideal choice for creating unobtrusive and stylish wearable devices. Moreover, ultra-fine glass is compatible with various manufacturing processes, enabling seamless integration with other technologies. It can be incorporated into flexible printed circuit boards (PCBs) or used as a substrate for flexible electronic components, allowing for more compact and efficient wearable devices. This compatibility with existing manufacturing methods facilitates the integration of ultra-fine glass into the production pipelines of wearable technology companies, streamlining the development and mass production of innovative devices. As wearable technology continues to evolve and push boundaries, the demand for ultra-fine glass is set to soar. Manufacturers are actively exploring new possibilities and pushing the limits of this remarkable material. From foldable smartphones to next-generation smart textiles, Ultra-Thin Glass is expected to play a significant role in shaping the future of wearable technology. Ultra- fine glass is revolutionizing the world of wearable technology. Its flexibility, exceptional optical properties, scratch resistance, lightweight nature, and compatibility with manufacturing processes have made it an indispensable material in the design and production of wearable devices. As advancements in technology continue to unfold, the use of ultra-fine glass is poised to reshape the landscape of wearable technology. When it comes to construction materials, finding the perfect balance between strength and style can be a challenge. However, one innovative solution has emerged in recent years: Wood Plastic Composite (WPC). This revolutionary material combines the natural beauty of wood with the durability and versatility of plastic, making it an ideal choice for a wide range of construction projects.

WPC is composed of wood fibers or flour blended with thermoplastics, such as polyethylene or polypropylene. The result is a unique material that inherits the best qualities of both wood and plastic. With its natural wood appearance, WPC brings warmth and elegance to any architectural design, while its plastic components provide exceptional strength, moisture resistance, and durability. One of the key advantages of WPC is its incredible strength-to-weight ratio. Despite being lightweight, Wood Plastic Composite boards and panels offer impressive structural integrity, making them suitable for various applications. From decking and fencing to cladding and outdoor furniture, WPC can withstand heavy loads and harsh weather conditions without warping, splintering, or rotting. This exceptional durability ensures that WPC structures retain their beauty and functionality for years to come. Unlike traditional wood, WPC requires minimal maintenance, making it a practical choice for busy homeowners and commercial property owners alike. WPC does not need to be stained, painted, or sealed to maintain its appearance and structural integrity. Simple cleaning with water and mild detergent is usually sufficient to keep WPC surfaces looking their best. This low-maintenance characteristic not only saves time and effort but also reduces long-term costs associated with upkeep and replacement. Moreover, WPC is an environmentally friendly alternative to traditional building materials. By utilizing recycled materials, such as wood scraps and plastic waste, Wood Plastic Composite helps reduce the demand for virgin resources and minimizes waste generation. Additionally, WPC does not contribute to deforestation, as it relies on wood fibers from sustainable sources. Its long lifespan and recyclability further enhance its eco-friendly credentials. In terms of design flexibility, WPC offers endless possibilities. It can be easily molded and shaped to create customized profiles, textures, and colors, enabling architects and designers to achieve their desired aesthetic vision. Whether mimicking the appearance of natural wood species or exploring contemporary finishes, WPC can adapt to any architectural style, seamlessly blending with its surroundings. Aside from its functional advantages, WPC also offers a wide range of design possibilities. With its natural wood appearance and grain patterns, WPC adds a touch of elegance and warmth to any construction project. It can be molded into various shapes and sizes, allowing for creative and customized designs. Whether you prefer a modern, sleek look or a rustic, traditional feel, Wood Plastic Composite can be tailored to suit your style and preferences. Furthermore, WPC is an environmentally friendly choice. By utilizing wood fibers derived from sustainable sources and recyclable plastic polymers, it reduces the reliance on natural timber and minimizes waste. The longevity of WPC also contributes to its sustainability, as it reduces the need for frequent replacements, thereby conserving resources in the long run. WPC offers the perfect balance of strength and style in construction. Its unique combination of wood fibers and plastic polymers results in a material that is both visually appealing and highly durable. With exceptional resistance to cracking, warping, moisture, and insects, WPC proves to be a long-lasting and low-maintenance option for various applications. Additionally, its design versatility and environmental benefits make it a preferred choice for those seeking sustainable and aesthetically pleasing construction materials. When it comes to finding the perfect material for your next project, WPC stands as a reliable and elegant solution. Wood Plastic Composite (WPC) is revolutionizing the construction industry by providing the perfect balance of strength and style. Its unique composition combines the natural beauty of wood with the durability and versatility of plastic, resulting in a material that is both aesthetically pleasing and highly functional. With its exceptional strength, low maintenance requirements, eco-friendly nature, and design flexibility, WPC is an ideal choice for a wide range of construction applications. Whether it's decking, fencing, cladding, or outdoor furniture, WPC delivers the best of both worlds, ensuring long-lasting and visually appealing structures for years to come. Wood Plastic Composite (WPC) has gained significant popularity in recent years as an alternative to traditional wood materials in outdoor applications. It combines the best qualities of both wood and plastic, offering enhanced durability, low maintenance requirements, and an appealing aesthetic. In this article, we will delve into the durability of WPC and explore its performance in various outdoor settings.

WPC is composed of wood fibers or flour and thermoplastics, typically a combination of polyethylene, polypropylene, or polyvinyl chloride. This unique blend creates a material that possesses the natural look and feel of wood while benefiting from the strength and weather resistance of plastic. One of the primary reasons Wood Plastic Composite is preferred in outdoor applications is its exceptional durability. Unlike natural wood, which is susceptible to rot, decay, and insect infestation, WPC is highly resistant to these issues. The plastic component shields the wood fibers, making the composite material less prone to moisture absorption and subsequent damage. As a result, WPC maintains its structural integrity and appearance over an extended period, even when exposed to harsh outdoor conditions. Another aspect that contributes to the durability of WPC is its resistance to fading and discoloration. Ultraviolet (UV) radiation from the sun can cause traditional wood materials to fade and lose their original color over time. However, WPC contains additives and pigments that provide protection against UV rays, allowing it to retain its vibrant color and aesthetic appeal for years without significant fading. Additionally, WPC exhibits excellent resistance to warping, splintering, and cracking, which are common issues faced by natural wood in outdoor environments. The plastic content in WPC prevents moisture absorption, reducing the chances of swelling or shrinking that can lead to warping. Furthermore, the absence of natural defects and knots in Wood Plastic Composite eliminates the risk of splintering, providing a safer and more comfortable surface for outdoor activities. When it comes to moisture-related concerns, WPC surpasses natural wood by being highly resistant to water damage, mold, and mildew growth. Its plastic component forms a protective barrier that prevents water penetration, making it an ideal choice for areas prone to heavy rainfall or high humidity. This resistance to moisture also contributes to the longevity of the material, as it prevents rot and decay that can compromise the structural integrity of traditional wood. In terms of maintenance, WPC offers significant advantages over natural wood. Unlike wood, which requires regular staining, painting, and sealing to preserve its appearance, Wood Plastic Composite only requires periodic cleaning with mild soap and water to remove dirt and debris. This low maintenance requirement saves both time and money, making WPC a cost-effective choice in the long run. While WPC boasts remarkable durability in outdoor applications, it is important to note that the performance of the material can vary depending on the quality of the product and the installation process. It is crucial to choose WPC from reputable manufacturers who adhere to high standards and use quality raw materials. Proper installation techniques, including adequate support structures and appropriate fasteners, also contribute to the long-term durability of WPC installations. Wood Plastic Composite (WPC) has proven to be a highly durable material for outdoor applications. Its resistance to moisture, UV radiation, rot, and insect infestation makes it an excellent alternative to traditional wood. With its low maintenance requirements and long-lasting performance, WPC offers a sustainable and aesthetically pleasing solution for outdoor decking, fencing, cladding, and other applications. By selecting high-quality products and ensuring proper installation, homeowners and businesses can enjoy the benefits of WPC for many years to come. |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

July 2023

Categories

All

|

RSS Feed

RSS Feed